Belt Fabrication Tools and Equipments

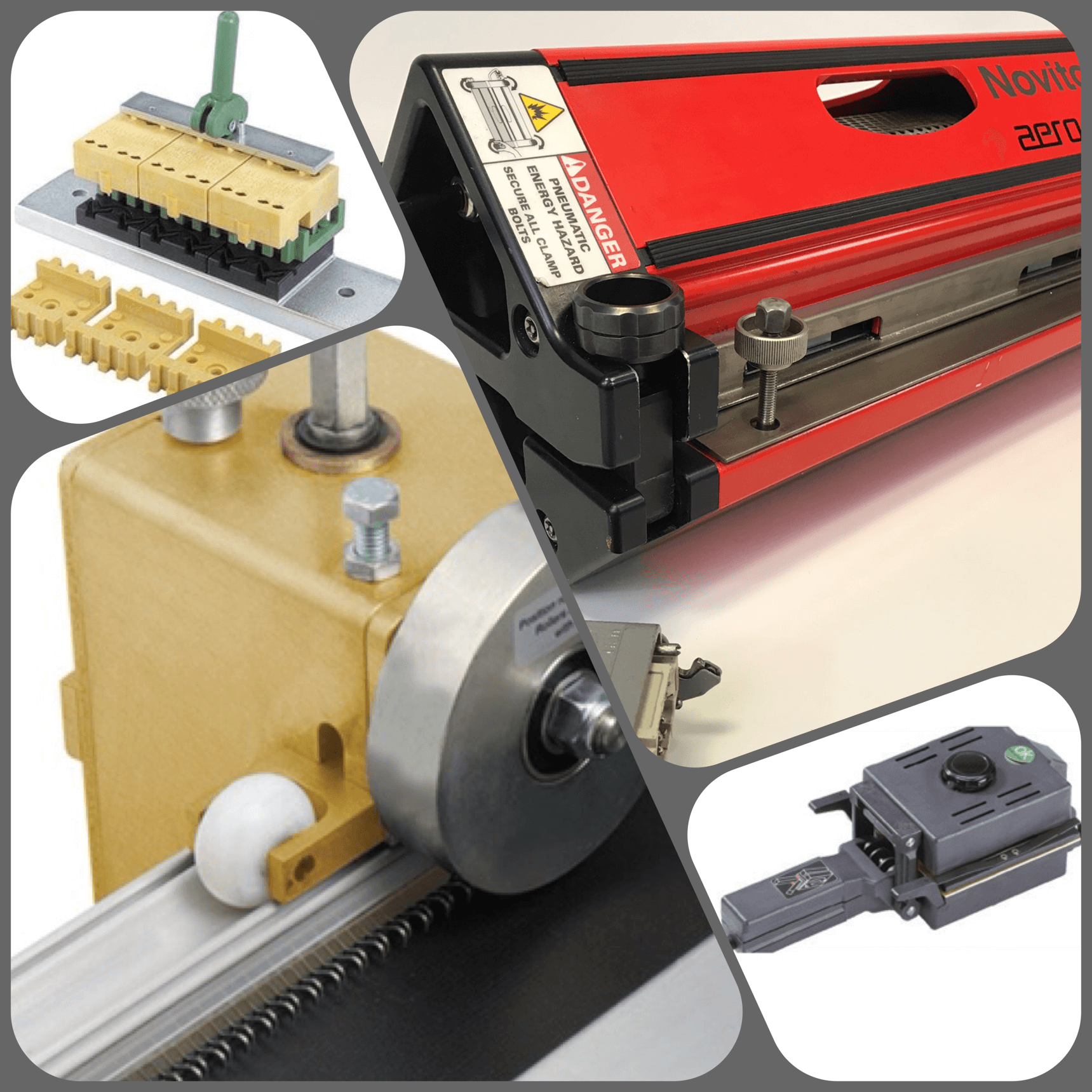

- Hot Presses: Engineered for consistent and precise belt splicing, our hot presses ensure strong, durable joints for various conveyor belt types and thicknesses.

- Cutting Machines: Designed for accurate cutting of conveyor belts to the required width and length, our cutting machines deliver clean, straight edges, minimizing waste and ensuring efficient fabrication.

- Guide Welding Machines: Perfect for attaching guides and profiles to conveyor belts, these machines provide secure and precise welding, enhancing belt performance.

- HF Machines: High Frequency (HF) welding machines are ideal for seamless welding of thermoplastic belts, ensuring a strong and uniform bond without the need for adhesives.

- Hot Blowers: Used for heating and reworking belt edges and profiles, hot blowers are essential for achieving a smooth finish and ensuring professional grade fabrication.

- Finger Punching Machines: Essential for preparing belt ends for splicing, our finger punching machines offer precise punching of finger joints, allowing for strong and reliable belt splices.

- Precision: Designed with advanced technology to ensure accurate cutting, welding, and splicing, resulting in high quality finished belts.

- Durability: Built to withstand heavy use in demanding environments, our tools offer long lasting performance with minimal maintenance.

- Ease of Use: User-friendly designs make our tools easy to operate, reducing training time and increasing efficiency in belt fabrication.

- Versatility: Suitable for a wide range of belt types and sizes, our tools provide flexible solutions for various fabrication needs.

- Reliability: Proven performance ensures consistent results, reducing the risk of errors and ensuring customer satisfaction.

- Manufacturing: Ensuring precise and efficient fabrication of conveyor belts for various production environments.

- Logistics: Supporting the fabrication of high-quality belts for use in distribution centers and warehouses.

- Food Processing: Providing tools for the fabrication of hygienic, FDA compliant belts used in food handling and processing.

- Pharmaceuticals: Offering equipment for the fabrication of belts used in cleanroom and sterile environments.

- Packaging: Ensuring reliable belt fabrication for the packaging industry, where precise and durable belts are essential.

PVC/PU Conveyor Belt Fabrication Tools and Equipment

At PROTECH, we are committed to providing industry leading fabrication tools and equipment that meet the demanding needs of conveyor belt distributors. As a trusted supplier, we offer a comprehensive range of tools and machinery designed for the efficient fabrication and maintenance of PVC and PU conveyor belts.

High Performance Fabrication Tools

Our PVC/PU conveyor belt fabrication tools and equipment are renowned for their precision, durability, and ease of use. Developed with advanced technology, these tools ensure accurate and reliable belt fabrication, helping distributors deliver high quality, customized belts to their clients.

Comprehensive Range of Fabrication Tools and Equipment

We offer an extensive selection of tools and equipment tailored for the specific requirements of PVC/PU conveyor belt fabrication. Our product lineup includes:

Key Advantages of Our Fabrication Tools

Applications

Our PVC/PU conveyor belt fabrication tools and equipment are trusted by belt distributors worldwide. They are used in a variety of applications, including:

Our Commitment to Excellence

At PROTECH, our commitment to excellence is reflected in the products we offer and the services we provide. We understand the critical role that high quality fabrication tools play in the success of belt distributors. Our team of experts is dedicated to helping you select the right tools and equipment for your specific needs, providing tailored support and technical assistance to ensure optimal performance.

Explore our range of PVC/PU conveyor belt fabrication tools and equipment and discover how we can help enhance your fabrication capabilities. Contact us today to learn more and find the perfect tools for your belt fabrication needs.